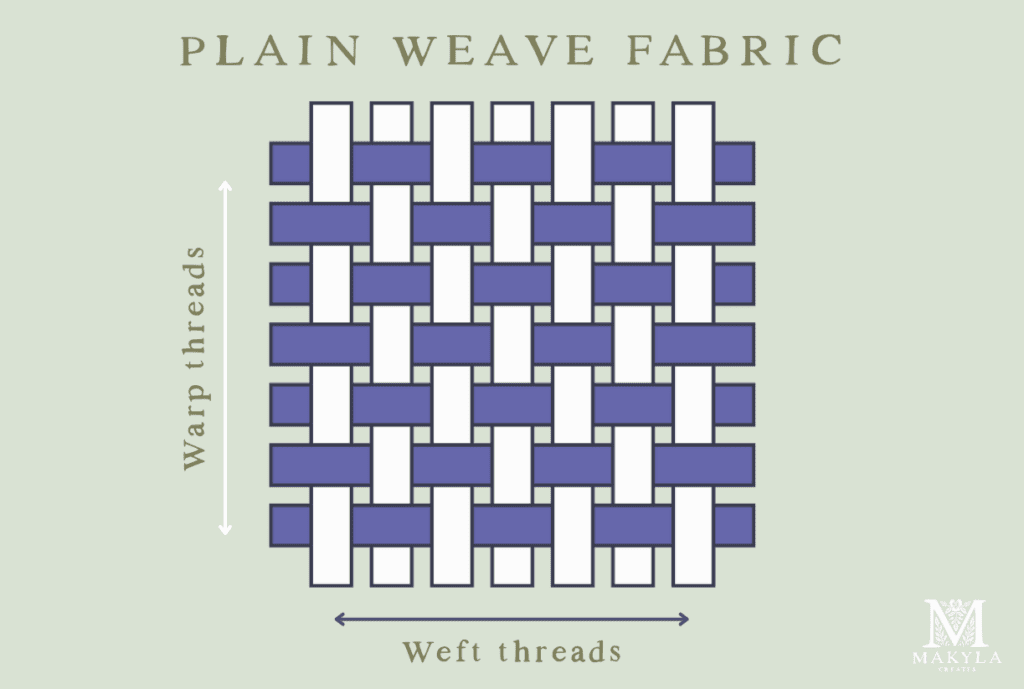

Woven fabrics are made by interlacing fibre threads together. The direction in which these threads are woven is called the warp and weft weave.

The warp thread runs along the length of the fabric and is also called the selvedge. The weft thread runs across the width of the fabric, from selvedge to selvedge. In this blog post, we’ll dive into the warp and weft threads, exploring their differences and why they are so important in the textile industry.

What Are Warp And Weft Threads?

In my guide to types of fabrics, I discuss the differences between woven and knit fabrics. The main difference is that woven fabrics are made from two essential things: warp and weft threads. Knit fabric is not.

Warp Threads – The warp threads in fabric are the vertical lines that provide support, running parallel to the edge of the cloth. They act as the foundation for the weft threads, which are woven horizontally. These threads are stationary during weaving, giving the fabric structure and stability. They are like the backbone of the textile, ensuring its integrity.

I like to remember that the warp thread is always the uncut edge of a fabric roll. This edge can sometimes have a white border or the fabric name and style name printed onto it. It is called the fabric selvedge.

Weft Threads – The weft threads are the horizontal lines interlacing with the warp threads, forming the fabric’s surface. They are also known as the horizontal threads or woof, moving back and forth through the stationary warp threads. Each yarn thread across the warp horizontally is called a “pick.” These threads add colour, pattern, and texture to the material, making it visually attractive.

I like remembering that the weft threads are shorter, creating the width of the fabric. The weft is the cut edge of the fabric.

The warp and weft threads influence fabric selection, pattern alignment, and the strength of seams. Knowing the direction of warp and weft can help ensure that your sewing projects turn out as intended and that you make the most of your chosen materials.

As an Amazon Associate, I earn from qualifying purchases. Read my full disclosure here.

Warp vs. Weft Strength

I’m sure you know by now that the warp threads, which run vertically, are usually stronger because they are longer and have to endure tension on the weaving loom. The weft threads that run horizontally create the fabric’s surface and give it its width.

It is common for sewing pattern grainlines to be cut along the selvedge, otherwise known as the warp direction. This makes clothing more comfortable and stronger by following the warp threads.

Garments can also be cut at 45-degree angles, called the bias. This means the sewing pattern is placed over the warp and weft threads at a 45-degree angle. When the fabric is draped, it falls with more stretch because the warp and weft threads are not vertical or horizontal.

Fabric Weaving Using Warp and Weft

Weaving is a timeless craft that has existed for thousands of years. It’s a way of creating clothing, shelter, and art that people have enjoyed throughout history. From ancient looms to modern weaving machines, the basic principles of warp and weft have remained the same.

The warp threads stay on the loom while the weft threads go in and out to make different patterns and thread counts. Before weaving begins, the warp threads might get special treatment to strengthen them. As for the weft, it’s more flexible since it has to move through the warp, which gives the final product a soft and versatile texture.

Types of Weaves

Warp and weft threads can be woven together uniquely to create different fabric textures and beautiful patterns. Take denim, for instance. It showcases a dominant blue warp thread, giving it its well-known appearance.

Here are three fundamental weaves:

1. Plain Weave – The most common and simplest weave, characterised by warp and weft threads crossing at right angles. It’s known for its durability and is used in cotton, linen, chiffon, and taffeta products.

2. Satin Weave – This refers to the weaving technique, not the fabric itself. Satin weave features four or more weft threads passing over a single warp thread, resulting in a shiny top and a matte back. It’s often used for lingerie, ties, blouses or fancy dresses.

3. Twill Weave – A twill weave is a pattern that creates a cool diagonal rib look. It’s made by passing the weft thread over two or more warp threads and then one more. It has a nice drape, making it perfect for all kinds of garments.

There are more weaves beyond plain, satin, and twill weaves. Countless other patterns can be used to create unique and interesting fabrics. For example, herringbone creates a cool zigzag design, while jacquard allows for really intricate and detailed patterns.

Thankfully the textile industry has evolved with technology! Thanks to computerised looms, we can now create beautifully intricate patterns that are precise and accurate, opening a whole new world of possibilities for textiles.

Warp and Weft Thread Counts

The thread count of woven fabrics is huge in their durability and ease of use. Fabrics with more warp and weft counts tend to be much sturdier and retain their shape well. On the other hand, fabrics that have lower thread counts may stretch and snag more easily. Thankfully, modern power looms have improved the density of the weft and often use lubricants in the warp threads to make the fabric even better.

Warp & Weft Conclusion

Knowing the roles of warp and weft threads can help you make better decisions when choosing and working with fabrics. These threads are like the hidden builders that create the fabrics we use or wear daily.